CMS:Number Three Electronic Switching System

The Number Three Electronic Switching System (3ESS) is an electronic switching system on the second floor of the Connections Museum. It was originally installed in 1980 as a Community Dial Office (CDO) in the village of Crosby, Washington and remained in service there until 1994.

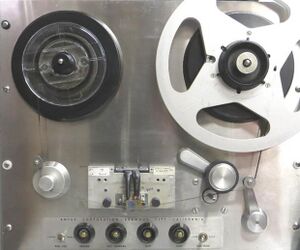

The 3ESS contains a custom tape drive emulator created by volunteers at the museum after the original tapes began to fail.

Museum life

In its early years at the museum, the 3ESS was cared for by volunteer Rich Barger (whose AT&T name tag is on the front of the switch) and æstrid Smith.

System failure

In 2002 the original boot tapes that the 3ESS used had become problematic. Eventually they had deteriorated beyond repair, and additionally the pinch roller in the 3ESS tape drives had significantly degraded. The switch was never powered off during this time period because of the predicted difficulty in booting it from the faulty tapes.

In 2009, the 3ESS froze for unknown reasons. During the reboot, the generic (the ESS's main program) failed to load from the tape. After some troubleshooting, the machine was powered down indefinitely.

Museum volunteers tried some hardware solutions to the problem such as installing new pinch rollers in both drives, but the tapes themselves were in such poor condition that reading them in the drives was impossible—any attempt to do so resulted in broken or hopelessly tangled tape. Eventually the switch was de-prioritized and remained off for several years.

Restoration

In 2019, a new effort to restore the machine to working operation began. This was a significant undertaking which required various skills from many different volunteers.

Chuck Huffington began with an extensive examination of past restoration efforts and began doing comprehensive hardware maintenance, including identifying, tagging, and replacing faulty circuit cards in the machine's two processors.

Dave Dintenfass disassembled a damaged tape and recorded the data as an audio track using a custom head block he fabricated mounted to a reel-to-reel tape machine at his recording studio, Full Track Productions. Dave played back the track at 3.75 inches per second, much slower than the original read speed of 30 inches per second. Sarah Autumn helped with the data transfer process and file management.

Andrew Sentman and Matt Mullins wrote a data-recovery program to extract the binary data from the audio. Because the blocks of data on the original tapes had checksums, they were able to verify the integrity of the final result.

Colin Slater built the v1 microcontroller that replaced tape machine 0 in the switch, read the binary data from a microSD card, and sent it to the tape data controller.

Once that was mounted in the machine, a year of debugging took place, where Colin and æstrid worked to reverse-engineer the tape drive controller commands and understand what the system needed in order to boot. This proved to be a very complex task, as some of the required documentation was missing entirely. This difficulty was further compounded by not having any available debugging tools other than a logic analyzer and an oscilloscope.

The v1 controller was replaced by an Atmel ATSAMD51J20A microcontroller in 2020.

In 2021, the machine booted successfully for the first time in years. It is now turned on ever Sunday so visitors can see it working.

Technical information

Power

The 3ESS has a custom powering solution. As originally manufactured, the 3ESS would cause a large inrush of current when turned on, lowering the voltage of the power supply. This was acceptable in practice because 3ESS units would rarely be powered cycled; they were designed to run for months or even years without turning off. However in the museum, the switch is turned on only on Sundays for tours or when being actively maintained by volunteers. The voltage drop from the inrush current would negatively affect the DMS-10 which shares its power supply, even causing the DMS-10 to crash. To solve this, volunteers installed a breaker system which allows smaller portions of the machine to be turned on individually, which draws less current and maintains the power supply voltage.

There are also components on the 3ESS which are sensitive to being turned on and off many times. Originally this would not have been a problem because the 3ESS was rarely power cycled, but in the museum configuration there are golf cart solenoid relays and large resistors between the power supply and the switch which handle the large current changes and protect sensitive electronics from wear and tear.